+86 186 3170 8948

+86 186 3170 8948

Jan. 16, 2025

In the world of fluid control systems, ball valves and gate valves are two of the most widely used types of valves, each offering unique advantages. Choosing the right valve depends on understanding their characteristics, operational differences, and suitability for specific applications. This article explores ball valves, gate valves, and their key distinctions to guide your decision-making process.

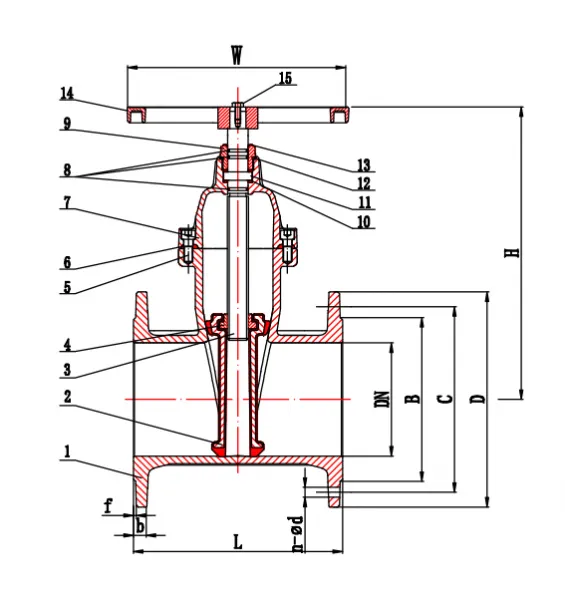

A gate valve is a type of valve that uses a sliding gate or wedge to open or close the flow of fluid. It is primarily designed for on/off control rather than throttling. The gate moves vertically to control the flow, and when fully open, it provides minimal resistance to fluid.

Typically used for isolation purposes in pipelines.

Requires multiple turns of the handwheel to open or close.

Offers excellent shut-off capabilities, especially in systems where full flow is required.

Commonly found in water supply systems, oil pipelines, and industrial processing plants.

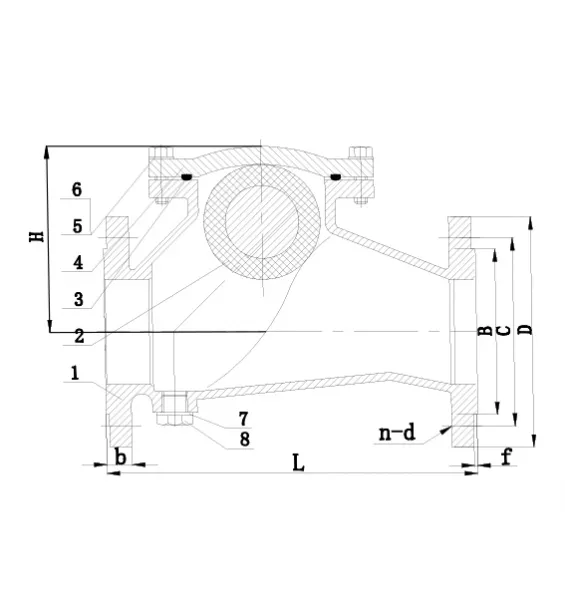

A ball valve uses a spherical disc with a hole through the center to control flow. Rotating the ball by 90 degrees aligns the hole with the flow path (open) or blocks it (closed). Ball valves are versatile and provide a reliable seal even after long periods of inactivity.

Designed for quick and easy operation, requiring only a quarter-turn to open or close.

Offers excellent sealing performance, even in high-pressure systems.

Commonly used in applications requiring frequent operation, such as chemical processing, HVAC systems, and water treatment plants.

Understanding the differences between gate valves and ball valves is crucial for selecting the right option. Below are the main distinctions:

Gate Valve: Utilizes a vertical gate or wedge that moves up and down to control fluid flow. Fully opening the valve eliminates obstructions, allowing smooth flow.

Ball Valve: Employs a spherical ball with a hole through its center. Turning the ball allows quick control of flow.

Gate Valve Structure

Ball Check Valve Structure

Gate Valve: Sealing relies on the gate pressing against the valve seat, which may wear out over time.

Ball Valve: Provides a tight seal, even after prolonged use, thanks to its precision-machined ball and seat.

Gate Valve: Requires multiple turns of the handwheel, making it slower to operate.

Ball Valve: Quick and straightforward, needing just a quarter-turn for full operation.

Gate Valve: Offers minimal resistance when fully open, as the gate does not obstruct the flow.

Ball Valve: May create slightly higher resistance due to the ball’s position within the flow path.

Gate Valve: Ideal for applications requiring full open or closed states, such as pipelines with minimal on/off operation.

Ball Valve: Better suited for frequent operation and where tight sealing is essential.

Gate Valve: More prone to wear and requires regular maintenance, especially in high-cycle operations.

Ball Valve: Durable and low-maintenance, making it suitable for demanding environments.

Gate Valve: Generally more affordable for larger diameters.

Ball Valve: Higher initial cost but offers longer-term savings due to durability and low maintenance needs.

| Aspect | Gate Valve | Ball Valve |

| Working Mechanism | Sliding gate for on/off control | Rotating ball with a hole for flow control |

| Sealing Performance | Relies on gate-seat contact | Tight seal with precision-machined components |

| Operation Speed | Requires multiple turns | Quick quarter-turn operation |

| Fluid Resistance | Minimal when fully open | Slightly higher due to internal structure |

| Best Applications | Isolation in pipelines | Frequent operation and tight sealing needs |

| Durability | Requires regular maintenance | Durable with minimal maintenance |

| Cost | Lower for larger sizes | Higher upfront, but cost-effective over time |

At Yaxing Valve Industry, we bring decades of expertise in designing and manufacturing high-quality industrial valves, including both gate valves and ball valves. With advanced production facilities and strict quality control measures, we deliver reliable solutions tailored to meet diverse industry requirements.

Our valves are built to international standards, such as BS, DIN, and AWWA, ensuring excellent performance in various applications, from water treatment and chemical processing to oil and gas pipelines. As a trusted partner, we provide not only superior products but also dedicated customer service to support your projects.

For more details about our valve solutions or to request a customized quote, visit www.yaxing-valve.com or contact our team directly.

Yaxing Valve Industry—your partner in precision and performance.

Previous post

Related Products

Botou Yaxing Fluid Equipment Co., Ltd. specializes in providing design, development, and manufacturing services for the water valve industry. We produce high-quality valve products.

+86 186 3170 8948

No.4 Road Botou Industrial Zone, Cangzhou City Hebei Province, China

Get Free Sample

Privacy Policy

Privacy Policy