+86 186 3170 8948

+86 186 3170 8948

Jan. 22, 2025

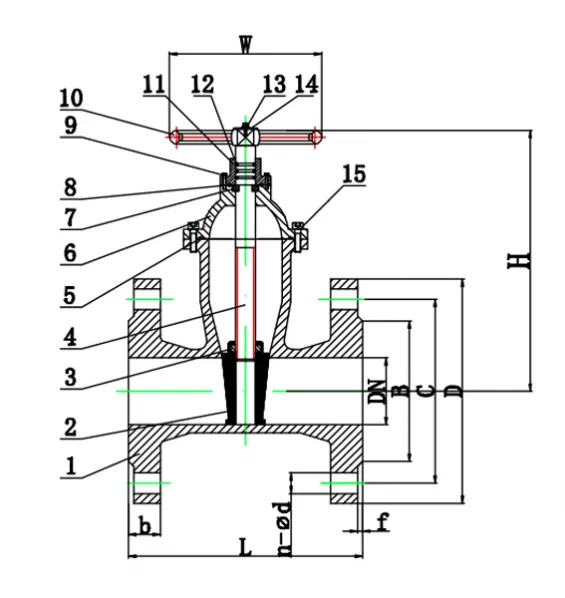

Gate valves, widely used for regulating the flow of liquids in pipelines, consist of various critical components. These components work together to ensure reliable performance and longevity under various operating conditions. Below, we introduce the common components of a Resilient Seated Gate Valve DIN3352 F4, highlighting their roles and materials.

Gate valves typically consist of multiple components, each designed with specific materials to suit its function. Here is an overview of the major parts:

Function: The body forms the main structure of the gate valve, housing all other components and providing a robust enclosure for fluid control.

Common Materials:

Ductile Iron GGG50: Known for its excellent strength and ductility.

Cast Iron: Often used for lower pressure applications.

Carbon Steel: Suitable for high-temperature and high-pressure systems.

Function: The wedge or disc is the movable part that blocks or allows fluid flow. It seals tightly against the seat to prevent leakage.

Common Materials:

Ductile Iron GGG50 with EPDM Coating: Provides resilience and corrosion resistance.

Stainless Steel: Preferred for its durability and resistance to corrosion in harsh environments.

Bronze: Used in specialized applications for its anti-corrosive properties.

Function: Transfers rotational motion from the handwheel or actuator to the stem.

Common Materials:

Brass: Offers good strength and corrosion resistance.

Phosphor Bronze: Provides excellent wear resistance in demanding applications.

Function: Connects the handwheel or actuator to the wedge, enabling vertical movement of the disc.

Common Materials:

Stainless Steel 420 (SS420): Known for its hardness and moderate corrosion resistance.

Stainless Steel 316: Offers enhanced resistance to corrosive environments.

Function: Creates a seal between the bonnet and the body to prevent fluid leakage.

Common Materials:

EPDM: Ideal for water and non-aggressive fluids.

Graphite: Suitable for high-temperature applications.

Function: Covers the top opening of the valve body and provides access for maintenance.

Common Materials:

Ductile Iron GGG50: Commonly used for its toughness.

Carbon Steel: For applications requiring strength and temperature resistance.

Function: Ensures proper alignment of the valve components during assembly.

Common Materials:

Brass: Offers good machinability and corrosion resistance.

Function: Provides a seal to prevent leakage around moving parts.

Common Materials:

EPDM: Used in water and mild chemical applications.

Nitrile Rubber (NBR): For applications involving oils and hydrocarbons.

Function: Secure the valve components together, ensuring structural integrity.

Common Materials:

Carbon Steel Grade 8.8: Known for its strength and durability.

A2-70 Stainless Steel: Offers corrosion resistance for outdoor and chemical environments.

Function: Used to manually operate the valve by turning the stem.

Common Materials:

Ductile Iron GGG50: Common for its durability.

Aluminum Alloy: Lightweight and corrosion-resistant for specific applications.

Function: Distributes load and prevents damage to surfaces during assembly.

Common Materials:

Carbon Steel: Used for general purposes.

Stainless Steel: For corrosion resistance.

Function: Houses the packing material that seals around the stem to prevent leakage.

Common Materials:

Ductile Iron GGG50: For standard applications.

Brass: Used in specialized environments requiring non-corrosive properties.

At Yaxing Valve, we prioritize material selection based on application needs, ensuring:

Durability: Materials withstand pressure, temperature, and wear.

Corrosion Resistance: Essential for longevity in aggressive environments.

Cost-Effectiveness: Providing solutions that balance quality and price.

By understanding the functions and material options for each component, you can select a gate valve tailored to your specific application. Yaxing Valve offers a wide range of gate valves, including the Resilient Seated Gate Valve DIN3352 F4, ensuring performance, reliability, and efficiency.

For more information, contact us or visit our website (https://www.yaxing-valve.com/) to explore our product catalog.

Related Products

Botou Yaxing Fluid Equipment Co., Ltd. specializes in providing design, development, and manufacturing services for the water valve industry. We produce high-quality valve products.

+86 186 3170 8948

No.4 Road Botou Industrial Zone, Cangzhou City Hebei Province, China

Get Free Sample

Privacy Policy

Privacy Policy