+86 186 3170 8948

+86 186 3170 8948

Knowledge

Dec. 03, 2024

A check valve is a crucial component in many fluid systems, designed to ensure that liquid or gas flows in only one direction. Its primary purpose is to prevent backflow, which can cause significant damage to pipes, pumps, and other system components. In this article, we will explore what a check valve does, its purpose, the different types available, their advantages and disadvantages, and the materials used to manufacture them. We'll also answer some frequently asked questions to help you make the right choice when selecting a check valve for your needs.

A check valve is a mechanical device that allows fluid to flow through it in one direction only. Its primary function is to prevent backflow, which can occur when the pressure in the system drops or when the flow direction reverses. When fluid flows in the correct direction, the valve opens, and when the flow reverses, the valve automatically closes to block it.

Check valves are used in a wide range of applications, including in water treatment plants, HVAC systems, fuel pipelines, and oil refineries. By preventing backflow, they protect critical components such as pumps, compressors, and even entire systems from damage caused by the unintended reversal of fluid.

The main purpose of a check valve is to:

Prevent backflow: Ensure that fluid flows in one direction only and automatically blocks reverse flow when needed.

Protect equipment: Prevent damage to pumps, compressors, and other system components caused by backflow.

Ensure system integrity: Maintain the proper pressure and flow within a system, reducing the risk of malfunction.

Enhance operational efficiency: By controlling the flow direction, check valves prevent energy losses and optimize system performance.

Applications include water distribution systems, oil pipelines, fuel systems, HVAC systems, and even food processing plants where backflow could contaminate clean liquids or cause system breakdowns.

Check valves come in various designs, each with its own advantages and ideal applications. Below are the four most common types of check valves used in different industries:

Characteristics:

The swing check valve is the most commonly used type of check valve. It features a hinged disc or flapper mechanism that swings open to allow fluid flow and swings shut when the flow reverses.

How it works:

When fluid flows in the correct direction, it pushes the disc or flapper open. When the pressure drops or reverses, the disc swings back into place, preventing backflow.

Applications:

Swing check valves are typically used in large pipelines and water supply systems. They are also used in sewerage systems and other applications that require a large flow capacity. The swing check valve is ideal for low-pressure environments but may not perform as well in high-pressure or low-flow systems.

Characteristics:

The ball check valve uses a ball that sits in a valve seat to stop reverse flow. When fluid flows in the correct direction, the ball moves away from the seat, allowing the fluid to pass. If the flow reverses, the ball returns to its seat, blocking the backflow.

How it works:

When fluid flows in the correct direction, it pushes the ball away from the valve seat, allowing fluid to pass. When flow stops or reverses, the ball moves back to the seat, sealing the valve.

Applications:

Ball check valves are common in smaller pipelines, drainage systems, and beverage industries where reliability is key, but the system does not need the high flow rates required by larger valves.

Characteristics:

The spring check valve uses a spring mechanism to open and close the valve. The spring holds the valve closed until the pressure of the flowing fluid overcomes the spring tension, opening the valve. When the pressure drops or reverses, the spring closes the valve.

How it works:

Fluid pressure opens the valve by overcoming the spring force, allowing the flow. When the pressure drops or the flow reverses, the spring forces the valve shut.

Applications:

Spring check valves are often used in small pumps and systems where precise pressure control is needed. They are commonly found in industrial machinery, HVAC systems, and low-flow applications.

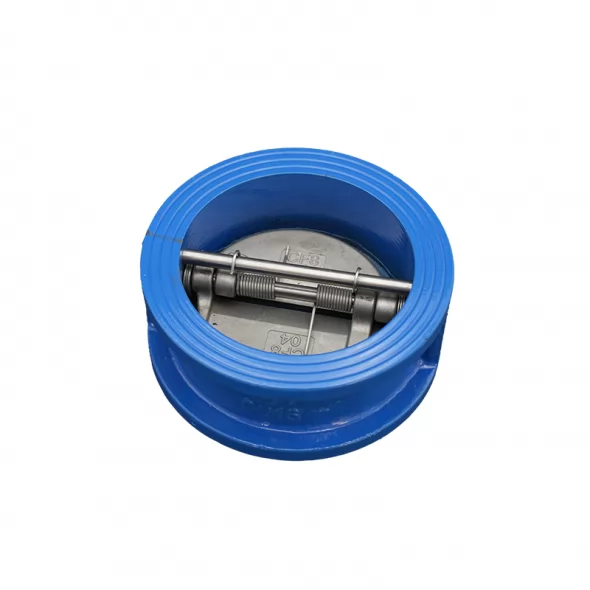

Characteristics:

The wafer check valve is a thin, compact valve that fits between flanges in a pipeline. This design allows for space-saving installation and offers excellent sealing properties.

How it works:

The valve opens when fluid flows in the desired direction and closes tightly when flow stops or reverses.

Applications:

Wafer check valves are ideal for applications where space is limited, such as in food processing, HVAC systems, and water treatment plants. Their compact design makes them suitable for high-pressure systems as well.

Advantages:

Prevents backflow: The primary advantage of a check valve is its ability to prevent backflow, protecting the entire system.

Reliability: Check valves are simple devices with few moving parts, ensuring reliability and long service life.

Cost-effective protection: By preventing damage to pumps and machinery, they reduce maintenance and repair costs in the long term.

Versatile applications: They are used in many industries, from water systems to oil pipelines.

Disadvantages:

Potential wear: Over time, check valves, especially those with moving parts, can wear out, especially under high pressure or constant operation.

Size and space: Some check valve types, such as swing check valves, require more space, making them unsuitable for compact systems.

Pressure limitations: Some check valves may not function properly at very high or very low pressures, depending on their design.

The materials used in the construction of check valves vary depending on the application and the conditions in which the valve will operate. Common materials include:

Metal check valves: Stainless steel, brass, and bronze are commonly used for their strength, durability, and corrosion resistance, especially in harsh environments.

Plastic check valves: PVC, CPVC, and polypropylene are more cost-effective and are ideal for low-pressure systems or systems involving chemicals.

Specialized materials: For extreme conditions, materials such as titanium, Hastelloy, and others may be used to resist high temperatures or corrosive fluids.

Answer: It depends on the application. Plastic check valves are suitable for low-pressure or chemical systems where corrosion resistance is important. Metal check valves are better for high-pressure systems and environments that require greater durability and strength.

Answer: No, check valves are designed to allow flow in only one direction. When flow reverses, the valve automatically closes to prevent backflow.

Answer: Cracking pressure is the minimum pressure required to open the check valve. This ensures that the valve doesn't open under low-pressure conditions, preventing leakage and improper operation.

Answer: No. A check valve is used to prevent backflow, while a control valve regulates or controls the flow, pressure, or temperature within a system.

Check valves play a vital role in ensuring the proper direction of fluid flow in various systems, protecting critical equipment from backflow and potential damage. Understanding the different types of check valves—swing, ball, spring, and wafer—helps in selecting the right one for specific applications. Whether you're managing a water treatment system, oil pipeline, or small pump, selecting the correct valve type and material is essential for maintaining efficiency, safety, and long-term performance.

Previous post

Related Products

Botou Yaxing Fluid Equipment Co., Ltd. specializes in providing design, development, and manufacturing services for the water valve industry. We produce high-quality valve products.

+86 186 3170 8948

No.4 Road Botou Industrial Zone, Cangzhou City Hebei Province, China

Get Free Sample

Privacy Policy

Privacy Policy