+86 186 3170 8948

+86 186 3170 8948

recommend products

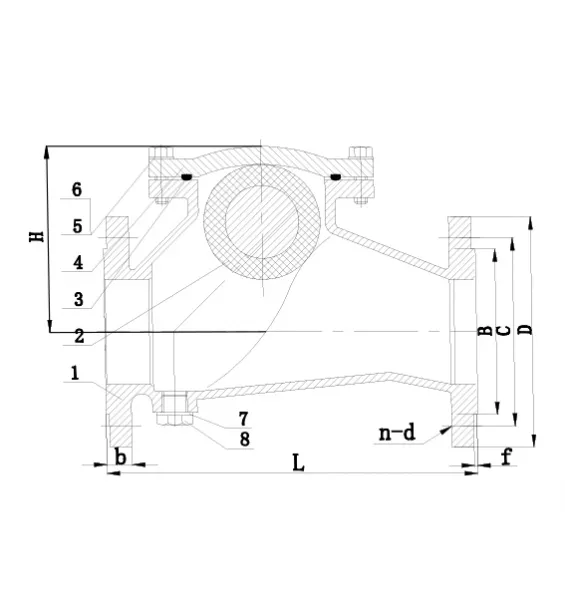

Let's crack open a ball check valve—literally. Using YAXING VALVE's DIN3202 F6 Ductile Iron Ball Check Valve as our guinea pig, we'll explore how these valves are built, what materials make them tick, and how to choose the right combo for your system.

This workhorse is designed for water, oil, and gas systems (up to 16 bar pressure). Here's what's inside:

| No. | Part | Material | Why It Works |

| 1 | Body | Ductile Iron GGG50 | Tough, shock-resistant, perfect for heavy-duty pipelines. |

| 2 | Ball | Carbon Steel (CS)/Ductile Iron + NBR Coating | Combines strength with a rubber layer for smooth sealing |

| 3 | O-Ring | NBR (Nitrile Rubber) | Flexible seal that handles oils and moderate temps (up to 100°C). |

| 4 | Bonnet | Ductile Iron GGG50 | Matches the body’s durability for uniform stress handling. |

| 5 | Bolts | A2-70 Stainless Steel | Corrosion-resistant, ideal for damp environments. |

| 6 | Washers | Stainless Steel + PTFE | Dual layers: stainless for strength, PTFE for chemical resistance. |

| 7 | |||

| 8 | Plug | Carbon Steel | Easy removal for maintenance without compromising strength. |

Compact design for easy installation in tight spaces.

NBR-coated ball reduces wear and ensures leak-free shutoff.

PTFE washers prevent seizing in corrosive or high-temperature fluids.

While YAXING's DIN3202 F6 uses industry-standard materials, here's how other setups compare:

Ductile Iron (GGG50): Default for cost-effective strength (water, oil).

Stainless Steel (SS316): For corrosive fluids (chemicals, seawater).

PVC/CPVC: Lightweight, chemical-resistant option for low-pressure systems.

Carbon Steel: Affordable, but needs coating (e.g., NBR, EPDM) for corrosion protection.

Stainless Steel: Bare metal works in corrosive environments; often paired with PTFE seals.

Aluminum: Lightweight for low-pressure air/gas systems.

NBR: Budget-friendly for oils and water (<100°C).

EPDM: Better for steam/hot water (up to 150°C).

PTFE/FKM: Handles aggressive chemicals (acids, solvents).

A4-80 Stainless: Upgrade for marine/saltwater applications.

Inconel: Extreme heat/corrosion resistance (refineries, chemical plants).

A ball check valve's lifespan hinges on matching materials to your fluid and environment:

Water/Oil: Stick with ductile iron + NBR/EPDM (like YAXING's F6 model).

Chemicals: Opt for SS316 body + PTFE seals.

High-Temp Steam: SS304/316 ball with graphite-filled seals.

Pro Tip: Always check chemical compatibility charts—for example, NBR fails with ketones, while PTFE laughs them off.

At YAXING VALVE, we've crafted ball check valves for 20+ years, from mining slurry systems to pharmaceutical cleanrooms. Our DIN3202 F6 isn't just a product—it's a tested solution with:

ISO 9001-certified manufacturing

Pressure-tested

Custom material kits

Stuck choosing materials? Let's solve it together. Reach our engineers at [info@civalves.com] or explore our technical guides at [https://www.yaxing-valve.com/knowledge/].

Related Information

Wafer Butterfly Valve Installation Guide | Step-by-Step Instructions & Expert Tips

Butterfly Valves Types and Different Butterfly Valve Classifications

Check Valves 101: Types, Uses, and How to Pick the Right One

Understanding the Difference Between Lug and Wafer Butterfly Valves

In Which Applications Are Resilient Seated Gate Valves Used?

Inside a Ball Check Valve: Structure, Materials, and Why It Matters

Differences Between Resilient Seated Gate Valve DIN3352 F4 and DIN3352 F5

The Role of Resilient Seated Gate Valves in Wastewater Treatment

Related News

+86 186 3170 8948

No.4 Road Botou Industrial Zone, Cangzhou City Hebei Province, China

Get Free Sample

Privacy Policy

Privacy Policy