+86 186 3170 8948

+86 186 3170 8948

recommend products

Let's talk about check valves—those unsung heroes in piping systems that keep fluids flowing in one direction and prevent messy backflow. Whether you're dealing with water, oil, gas, or aggressive chemicals, choosing the right check valve matters. Below, we'll break down common types, their best uses, and tips for selecting the perfect fit.

How it works: A hinged disc swings open with flow and slams shut when flow stops.

Best for: Large pipes, low-flow velocity systems (e.g., water treatment, HVAC).

Watch out: Can cause water hammer in fast-reversing flows.

How it works: A free-floating ball lifts with flow, drops back to seal when flow stops.

Best for: Viscous liquids or slurries (think wastewater, mining).

Bonus: Simple design, easy maintenance.

How it works: A flexible rubber flap bends open under pressure, snaps closed.

Best for: Sewage, stormwater systems—handles debris like a champ.

Weak spot: Not ideal for high temps or chemicals.

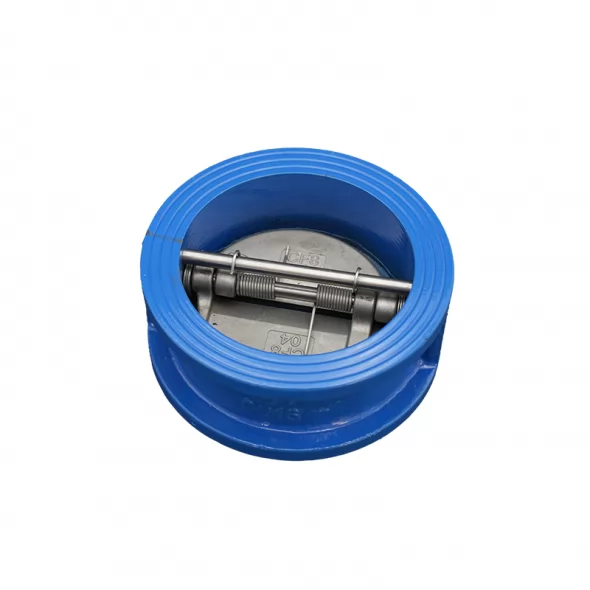

How it works: Two spring-loaded plates open/close simultaneously.

Best for: Tight spaces (no flange needed!), moderate-pressure systems (oil & gas).

Perk: Lightweight and affordable.

How it works: Mini ball valve design for threaded connections.

Best for: Small residential/commercial systems (e.g., plumbing, irrigation).

Pro tip: Go for stainless steel if corrosion's a concern.

How it works: A spring forces the disc closed instantly, eliminating slam noise.

Best for: Quiet environments (hospitals, labs) or vertical installations.

Why we love it: Zero water hammer, space-efficient.

How it works: A disc tilts on a pivot, reducing wear in high-velocity flows.

Best for: Steam systems, high-pressure oil/gas pipelines.

Key advantage: Handles rapid flow reversal smoothly.

Don't pick blindly—ask these first:

Fluid type: Is it corrosive? Viscous? Slurry? (e.g., rubber flaps hate chemicals.)

Flow direction: Vertical or horizontal? (Spring valves work both ways.)

Pressure rating: High-pressure systems need metal valves; low-pressure can use plastics.

Maintenance access: Can you easily clean or replace parts? (Ball valves win here.)

Noise tolerance: Got neighbors? Silent spring valves save the day.

Hi there! We're YAXING VALVE, a check valve manufacturer with over 20+ years of grit in the industry. From rubber flaps for muddy wastewater to high-pressure tilting discs for offshore rigs, we've engineered solutions for 50+ countries.

Our valves aren't just products—they're built to last, with ISO-certified materials and rigorous testing. Whether you're a contractor, plant manager, or DIY wizard, we'll help you avoid costly leaks, downtime, or that awful water hammer noise.

Need a valve that actually works? Let's chat! Drop us a line at [info@civalves.com] or explore our catalog at [https://www.yaxing-valve.com/check-valve/].

Related Information

Wafer Butterfly Valve Installation Guide | Step-by-Step Instructions & Expert Tips

Understanding the Difference Between Lug and Wafer Butterfly Valves

Inside a Ball Check Valve: Structure, Materials, and Why It Matters

The Role of Resilient Seated Gate Valves in Wastewater Treatment

Check Valves 101: Types, Uses, and How to Pick the Right One

In Which Applications Are Resilient Seated Gate Valves Used?

Differences Between Resilient Seated Gate Valve DIN3352 F4 and DIN3352 F5

Related News

+86 186 3170 8948

No.4 Road Botou Industrial Zone, Cangzhou City Hebei Province, China

Get Free Sample

Privacy Policy

Privacy Policy